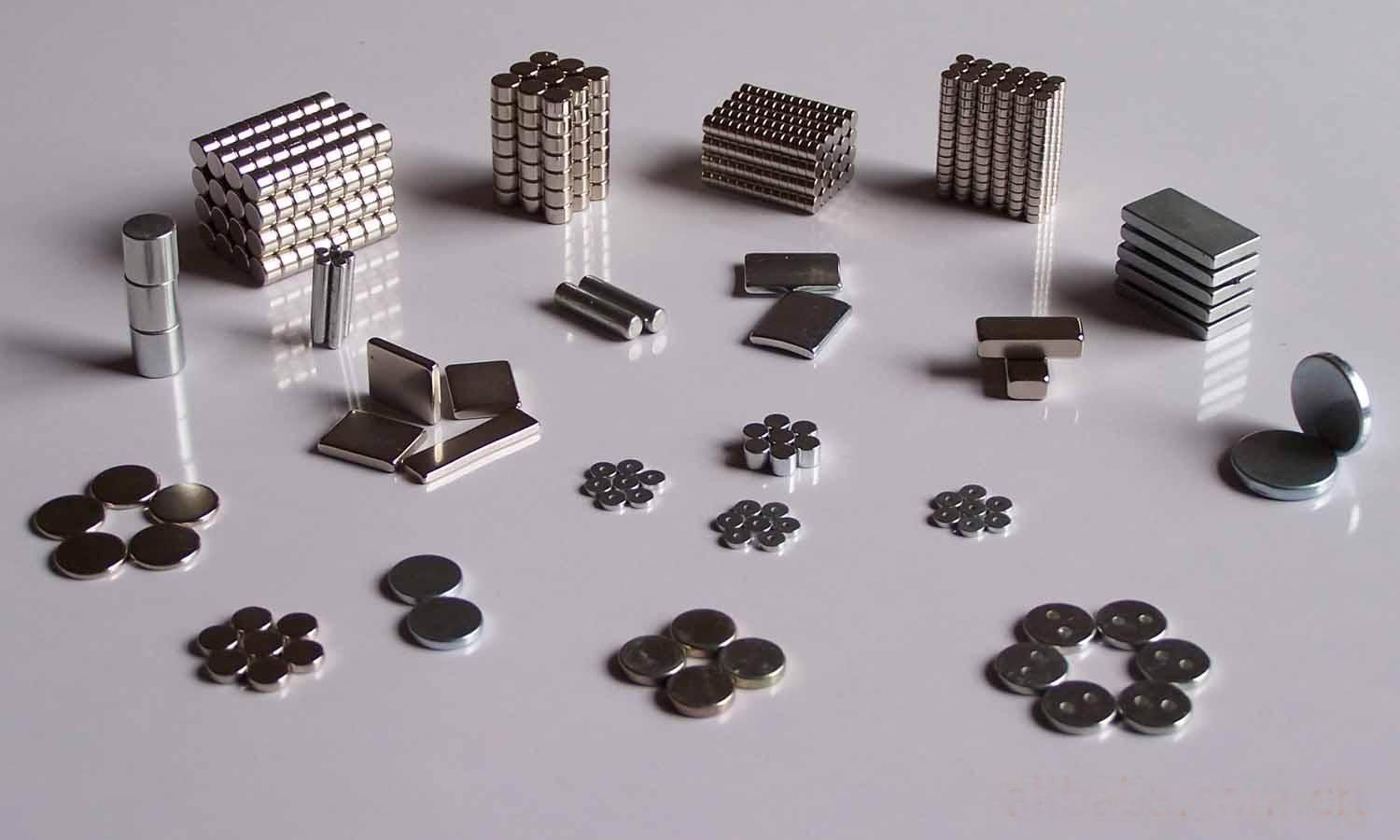

The most used magnetic materials sintered NdFeB magnets, SmCo Magnets, AlNiCo magnet and Ceramic magnets are compared from different aspects as follows:

Prices:

SmCo magnets the most expensive, Sintered NdFeB magnets the second and the cheapest is Cermaic magnets;

Intrinsic coercive force:

SmCo almost equal sintered NdFeB magnets in the highest Hcj value, the Hcj of Ferrite magnets is the lowest;

Max product energy:

SmCo magnets reach 32 MGOe but Sintered NdFeb can reach 52MGOe;

Max working temp:

AlNiCo won the first place so it is mostly used in meters, SmCo reach to 350 degrees, while NdFeB only up to 230 degrees;

and machinability:

As Neodymium magnets and SmCo magnets are very fragile, they are limited in machinability. Ferrite magnets are mostly moulded and cut without that much machining like other magnetic materials.

Prices:

SmCo magnets the most expensive, Sintered NdFeB magnets the second and the cheapest is Cermaic magnets;

Intrinsic coercive force:

SmCo almost equal sintered NdFeB magnets in the highest Hcj value, the Hcj of Ferrite magnets is the lowest;

Max product energy:

SmCo magnets reach 32 MGOe but Sintered NdFeb can reach 52MGOe;

Max working temp:

AlNiCo won the first place so it is mostly used in meters, SmCo reach to 350 degrees, while NdFeB only up to 230 degrees;

and machinability:

As Neodymium magnets and SmCo magnets are very fragile, they are limited in machinability. Ferrite magnets are mostly moulded and cut without that much machining like other magnetic materials.